Pipeline Integrity Management System (PIMS)

Monitor • Analyse • Protect • Optimize Pipeline Health

The α-phe PIMS a Pipeline Integrity Management System developed by Ankaa Consulting provides a complete lifecycle framework for managing onshore and offshore pipelines. The module centralizes design data, inspection results, defect assessments, corrosion monitoring, and risk evaluation into one unified platform. It enables operators to maintain pipeline integrity, reduce operational risks, and comply with global pipeline standards including DNV-OS-F101, DNV-RP-F116, ASME B31.8S, and API RP 1160.

Built on the α-phe Platform, PIMS delivers industry-leading functionality through a modern, cloud-ready, workflow-driven application.

Built on the α-phe Platform

The PIMS module is powered by the α-phe platform’s enterprise features:

- Unified asset and integrity database

- Advanced dashboards and analytics

- Workflow automation and approvals

- Comprehensive audit trails

- Role-based access control

- Flexible on-premise or cloud deployment

- Integration with ERP/CMMS (SAP, Maximo, Oracle EAM)

Comprehensive Pipeline Integrity Management

Pipeline Design Data & Segmentation

Capture, organise, and manage all pipeline design and operational parameters:

- Onshore and offshore pipeline definitions

- From/to coordinates, KP positions and GPS mapping

- Length, diameter, material grade and coating

- Design life, installation year, MAOP and operating conditions

- Segment-level integrity attributes

Segmentation supports accurate RBI, inspection planning and integrity assessments across different pipeline environments.

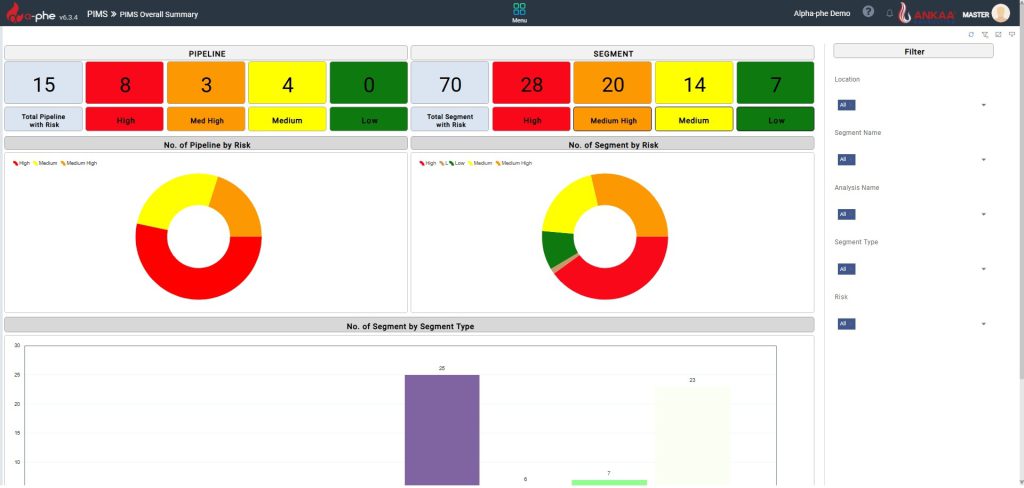

Risk-Based Inspection (RBI) for Pipelines

A full RBI framework is integrated into the PIMS module, enabling risk-driven decision-making.

Features include:

- Initial threat screening

- Onshore and offshore RBI models

- Probability and consequence calculations

- Internal and external corrosion risk analysis

- Third-party damage and geohazard risk evaluation

- Configurable consequence categories (Safety, Environmental, Financial, Reputation)

- Confidence factor and development factor adjustments

- Risk matrix visualisation

- Optimised inspection intervals

RBI results directly drive recommended actions and inspection plans.

Inspection Planning & Integrity Monitoring

α-phe PIMS centralises the planning and execution of all pipeline inspections:

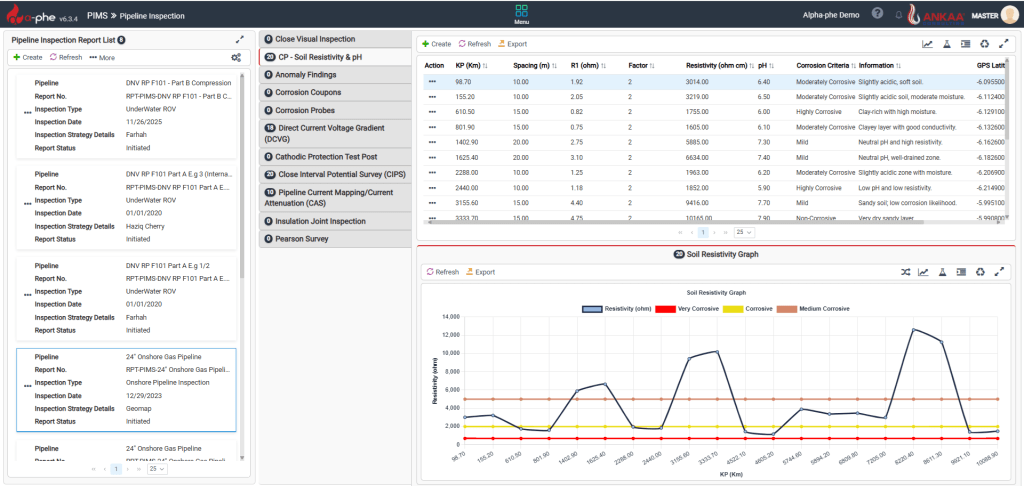

In-Line Inspection (ILI) Management

- Support for MFL, UT, Caliper and geo-pig inspections

- Recording of anomalies including metal loss, dents, buckles, gouges and ovality

- Interactive assessment of remaining life and MAOP impacts

Cathodic Protection (CP) Management

- CIPS and DCVG survey data logging

- Potential measurements and CP system condition

- Cover depth measurements and soil characteristics

Close Visual & Condition Monitoring

- External coating condition

- Corrosion monitoring and probes

- UT wall thickness measurements

- Vibration, settlement and environmental data

- Sludge and internal condition sampling

All inspection datasets feed directly into the FFS and RBI engine for continuous integrity assessment.

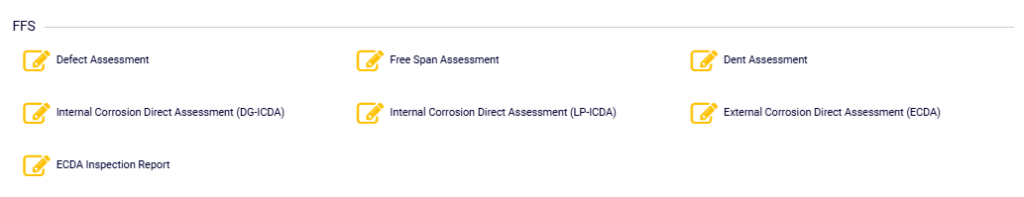

Fitness-for-Service (FFS) & Defect Assessment Tools

The module incorporates advanced evaluation tools aligned to recognised pipeline integrity methodologies.

Supported assessments include:

- Defect Assessment (corrosion)

- Dent Assessment

- Free-Span Analysis

- ICDA – Internal Corrosion Direct Assessment

- ECDA – External Corrosion Direct Assessment

Each assessment provides clear outputs for:

- Acceptability of defects

- Allowable operating limits

- Recommended repair/monitoring/mitigation

- Remaining life and re-inspection intervals

- MAOP validation

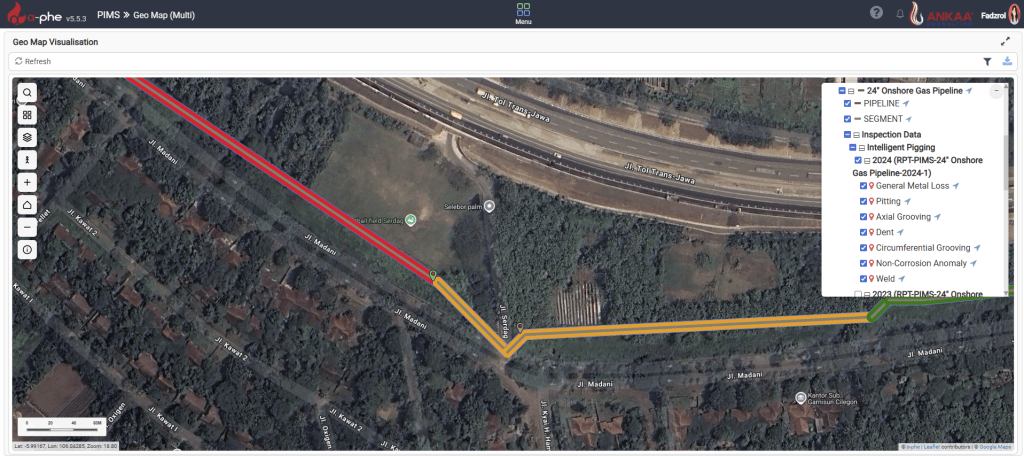

Geo-Spatial MAP View

Visualise the entire pipeline network on an interactive map:

- Full pipeline route plotted using GPS coordinates

- Segment-level colour coding (risk, status, inspection results)

- View inspection status (planned, in progress, completed, overdue)

- Overlay threat data, defect locations and CP performance

- Click-through to segment details, inspection history and defect logs

- Filters for pipeline, segment, status, risk level, inspection type and threat category

The MAP view provides real-time spatial awareness for pipeline operators.

Actions, Work Orders & Mitigation Planning

Based on RBI, FFS and inspection results, α-phe PIMS generates:

- Repair recommendations

- Follow-up inspections

- Pressure reduction measures

- Mitigation plans

- Monitoring requirements

- Work scopes and task lists

When integrated, these can be exported to CMMS systems such as SAP, Maximo or other CMMS.

End-to-End PIMS Workflow

- Define pipeline data and segmentation

- Configure risk model and inspection strategy

- Conduct RBI to prioritise integrity activities

- Plan ILI, CP, UT and visual inspection campaigns

- Capture inspection results and anomaly data

- Perform FFS and defect assessments

- Generate mitigation actions and work orders

- Monitor pipeline integrity via dashboards and MAP view

Key Benefits of α-phe PIMS

- Full lifecycle pipeline integrity management

- Data-driven decision-making using RBI + FFS

- Accurate inspection planning and risk controls

- Integrated geo-spatial visualisation

- Complete audit trail and regulatory compliance

- Reduces manual spreadsheets and disconnected workflows

- Enables prioritisation of critical threats and segments

- Scalable across networks, regions and multiple pipeline systems

Industries Supported

- Gas transmission and distribution

- Offshore pipelines and shore-approach systems

- Hazardous liquid pipelines

- Petrochemical and refinery pipelines

- Cross-country pipelines

- Pipelines in high-consequence or corrosion-sensitive zones

Request a Demonstration

Experience how the α-phe Platform and PIMS module can enhance your pipeline integrity program.

Contact our team to schedule a live demonstration.

Request for free Demo / Quote

Schedule a 30 minute to 1hr call

In the 30-minute to 1hr call we will demonstrate the software and explain the concept around the software, we will clarify all the queries you may have. The demo will be scheduled over Microsoft Teams. The link to connect will be provided after reviewing the submission of the request for free demo form below.