α-phe Risk-Based Inspection (RBI) is a systematic and structured approach to identifying and evaluating the risk associated with equipment or processes, and determining the most effective inspection plan. RBI takes into consideration the likelihood and consequence of equipment failure, as well as the potential impact on safety, environment, and production. The RBI process uses risk analysis techniques to prioritize equipment for inspection and maintenance, ensuring that inspection resources are allocated in the most effective and efficient way.

API 581 is a Recommended Practice (RP) developed by the American Petroleum Institute (API) for conducting RBI for pressure vessels, piping systems, and storage tanks. API 581 provides guidelines and procedures for assessing the risk of equipment failure and developing inspection plans based on that risk assessment. The API 581 methodology includes the use of inspection and operational data, as well as engineering analysis, to identify and evaluate the risk of equipment failure.

Ankaa Consulting can provide a range of services to assist you in RBI journey:

- To Review and align Asset register for RBI and CMMS (SAP/MAXIMO) systems.

- To Manage and centralise the Mechanical and process design data

- To analyze the consequences of failure in quantitative and qualitative approaches

- To analyze the likelihood of Failure using different Damage Modes and Mechanisms

- To comply with all applicable governing regulations and guidelines

- Develop a cost-effective inspection and maintenance program

- Define Corrosion Loops, considering the material and process conditions and derive theoretical corrosion rates

- Review inspection reports and gather wall thickness data for deriving measured corrosion rates

- Prioritize inspecton based on risk based approach, Focus your inspection activities for the equipments and components that has the highest risks

- Define Corrosion Monitoring Location (CML) in isometrics

- Integrate with CMMS (SAP/MAXIMO) to plan inspection schedules

Continuous Improvement RBI Solution

α-phe RBI software cover all the Damage Modes as per the API 581

- Thinning (both general and local)

- Component lining damage

- External damage (thinning and cracking)

- Stress Corrosion Cracking (SCC)

- High Temperature Hydrogen Attack (HTHA)

- Mechanical fatigue (piping only)

- Brittle fracture

α-phe Risk-based inspection software is designed to help companies manage risk associated with equipment failure by identifying and prioritizing equipment for inspection and maintenance. Some of the functionalities typically included in RBI software are:

- Equipment database: RBI software includes a database that contains information about the equipment being inspected, including the equipment type, location, design parameters, and historical inspection data.

- Risk assessment: RBI software uses risk analysis techniques to assess the likelihood and consequence of equipment failure, taking into consideration factors such as the age of the equipment, the operating conditions, and the potential consequences of a failure.

- Inspection planning: Based on the risk assessment, RBI software helps companies develop inspection plans that prioritize the inspection of equipment that has the highest risk of failure. This includes defining inspection intervals, inspection techniques, and the scope of the inspection.

- Reporting: RBI software generates reports that summarize the results of the risk assessment and inspection plans. These reports provide information on the overall risk level of the equipment and the effectiveness of the inspection program.

- Integration: RBI software can integrate with other systems, such as CMMS or ERP systems, to help streamline the inspection and maintenance process and ensure that inspection and maintenance activities are properly scheduled and executed. Seamlessly integrates with other modules in α-phe to create full holistic approach to RBI and AIMS processes.

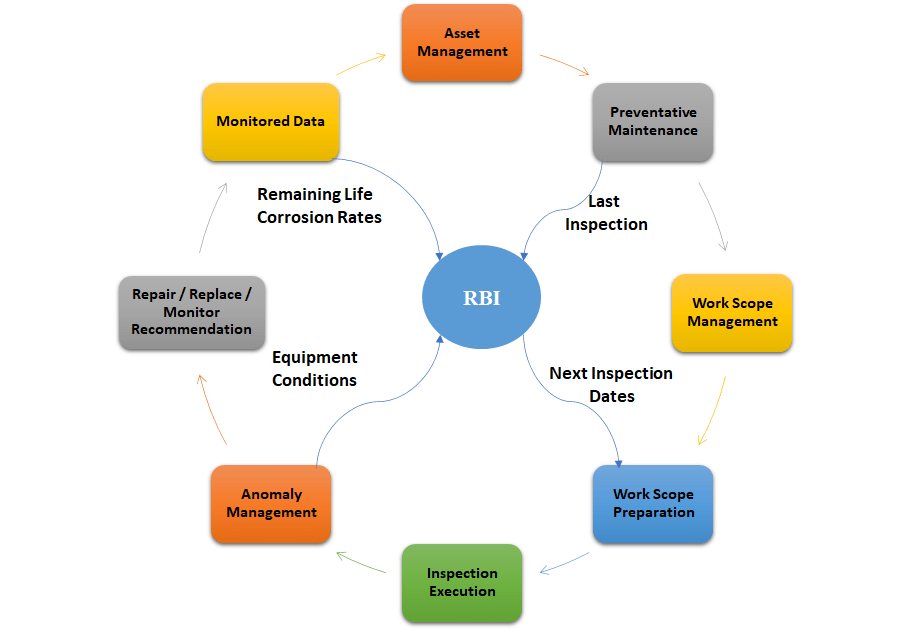

Ankaa Consulting’s α-phe RBI software provides a comprehensive solution for managing risk-based inspection projects and ensuring continuous improvement in asset integrity management. By integrating with Asset Integrity Management Systems (AIMS), the α-phe RBI software allows operators to perform a plan-do-check-act cycle as an AI process, which can help streamline the inspection and maintenance process and ensure that inspection and maintenance activities are properly scheduled and executed. The continuous improvement RBI solution also allows for re-assessments to be performed with minimal effort, reducing the time and resources required for future inspections. By providing a fully integrated and connected solution, Ankaa Consulting’s α-phe RBI software can help companies overcome the challenges of performing RBI and improve the overall performance of their assets.

Request for free Demo / Quote

Schedule a 30 minute to 1hr call

In the 30-minute to 1hr call we will demonstrate the software and explain the concept around RBI software, we will clarify all the queries you may have. The demo will be scheduled over Microsoft Teams. The link to connect will be provided after reviewing the submission of the request for free demo form below.