Proactive Integrity Control Through IOW Monitoring

The α-Phe Integrity Operating Window (IOW) module empowers asset integrity and process safety teams to define, monitor, and manage critical operating limits that prevent damage to equipment and ensure long-term reliability of assets.

By integrating real-time process data and laboratory inputs, α-Phe IOW enables early detection of integrity threats, improves compliance with industry standards like API RP 584, and strengthens your organization’s overall Asset Integrity Management System (AIMS).

What Is an Integrity Operating Window (IOW)?

An Integrity Operating Window is a defined set of safe operating limits for key process parameters such as temperature, pressure, flow rate, or chemical concentration that are directly linked to the degradation mechanisms of materials and equipment.

Operating outside these limits may lead to accelerated corrosion, metallurgical damage, or loss of containment. IOWs act as protective thresholds to ensure that process conditions do not compromise the mechanical integrity of assets.

Why Are IOWs Critical?

- Traditional DCS alarms focus on process stability, not equipment health or long-term integrity.

- Unnoticed or unmanaged excursions can lead to early equipment failure, safety incidents, and costly downtime.

- Regulatory and industry frameworks (e.g. API 584, API 571) increasingly require a structured approach to integrity monitoring.

- Many facilities lack a unified system to link excursions with investigation, mitigation, and inspection workflows.

Key Benefits of the α-Phe IOW Module

- Define IOWs based on damage mechanisms and asset design parameters

- Set Normal, Alert, and Action limits with real-time monitoring

- Integrate live data from Production Historians and LIMS systems

- Trigger automatic notifications and investigation workflows upon breaches

- Track cumulative damage exposure and duration of excursions

- Link IOW events to inspection plans, anomaly management, or MOC

- Visualize active excursions, performance KPIs, and asset health dashboards

- Maintain an auditable history of all breaches and actions taken

How the IOW Module Works in α-Phe

1. Define Operating Limits

Users configure process parameters for each critical asset or system, defining Normal, Alert, and Action thresholds. These limits are based on:

- Materials of construction

- Known degradation mechanisms (per API 571)

- OEM recommendations

- Site experience or previous failures

2. Asset Integration

Each IOW is linked to the relevant corrosion loops, equipment or system within α-Phe’s centralized asset hierarchy, ensuring clear traceability to:

- Static equipment

- Process units

- Inspection strategies

- Risk-based maintenance plans

3. Real-Time Monitoring

The α-Phe platform collects live data from:

- Production Historians (e.g., PI System, Honeywell PHD)

- LIMS (Laboratory Information Management Systems)

These integrations enable:

- Automated excursion detection

- Alert generation based on threshold breaches

- Exposure duration tracking

4. Excursion Handling & Workflows

When an excursion occurs:

- The system logs the breach with timestamp and severity

- Notifications are sent to responsible personnel

- A pre-configured investigation and resolution workflow is launched

- Users can assign root cause, mitigation actions, and follow-ups

- Related tasks are automatically linked to inspection or repair schedules

Integration with Production Historian & LIMS

The α-Phe IOW module supports seamless data integration to enable continuous and accurate monitoring:

🔹 Production Historian Integration

- Fetches real-time values of pressure, temperature, flow, and more

- Detects process excursions immediately

- Enables cumulative damage analysis over time

🔹 LIMS Integration

- Imports lab-analyzed parameters (e.g., H2S, chlorides, amines, pH, sulfur)

- Compares against predefined chemical IOW thresholds

- Flags delayed or batch-based exceedances not visible in DCS

These integrations ensure that both continuous and discrete data sources contribute to a complete IOW monitoring framework.

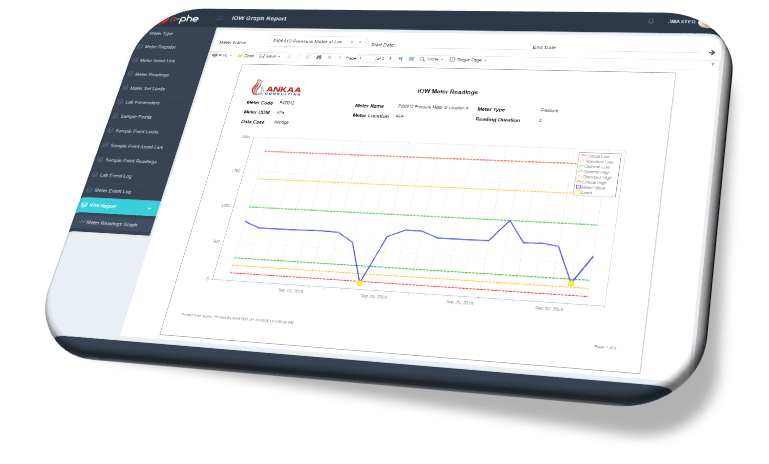

Dashboards and Reporting

The α-Phe IOW module provides built-in dashboards and reports tailored for integrity, operations, and HSE teams:

- Assets in excursion state

- Cumulative exposure hours per IOW

- IOW breaches by system, severity, or cause

- Pending vs. resolved investigations

- Time to acknowledge / resolve metrics

All data can be exported or visualized within α-Phe’s central dashboard interface.

Secure, Scalable, and Industry-Compliant

- Built-in support for API RP 584, API 571, API 580

- Secure access controls and audit logging

- Supports multi-site deployment and cross-facility comparison

- Integrates with α-Phe’s broader AIMS modules: Inspection, RBI, MOC, Anomaly, and Work Management

Ready to Strengthen Your Integrity Monitoring?

The α-Phe IOW module bridges the gap between process safety and asset integrity with a smart, integrated, and standards-based approach. Let us show you how it works in your environment.

👉 Book a Demo below

Request for free Demo / Quote

Schedule a 30 minute to 1hr call

In the 30-minute to 1hr call we will demonstrate the software and explain the concept around the software, we will clarify all the queries you may have. The demo will be scheduled over Microsoft Teams. The link to connect will be provided after reviewing the submission of the request for free demo form below.