A modern and comprehensive cloud based Reliability Centered Maintenance (RCM) platform that can be deployed with optimum efficiency.

α-phe performs RCM analysis using FMEA using John Moubray RCM2 methodology and compliant to SAE JA1012 and SAE JA1011. The application of RCM leads to greater safety, environmental integrity, higher reliability and uptime, lower maintenance cost and higher motivation of workforce.

α-phe RCM does so by asking the following seven questions:

- What are its functions (what do its users want it to do)?

- In what ways can it fail (functional failures)?

- What causes it to fail (failure modes)?

- What happens when it fails (failure effects)?

- Does it matter if it fails (consequences of failure)?

- Can anything be done to predict or prevent the failure?

- What do we do if we cannot predict or prevent the failure?

α-phe RCM considers the following recommendations:

- Predictive maintenance

- Condition-based maintenance

- Preventive maintenance

- Failure finding tasks)

- training, procedures, redesigns

- Run-to-failure

α-phe RCM features and Functionality Includes the following

- Asset Registration for RCM based on ISO 14224

- Asset Property / attribute definition per tag class

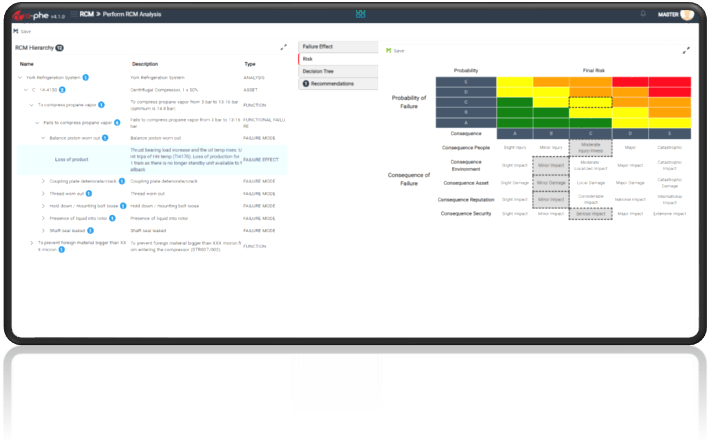

- Criticality Assessment approaches FMEA / FMECA

- Configurable Risk Matrix

- Task Selection Roadmap asks for RCM questions

- Connection to existing Jobs / OEM

- Create PM tasks from the Task Selection

- Create PM / CM Recommendations

- Sanity Check of selected PM Task

- Integrate with CMMS Software like SAP, MAXIMO, etc…

- Reports – Printable

- Oreda Data references for failure rate

- Store all assessment related document with the FMEA data.